XIOX-500-05A Plasma jet module

This equipment uses normal pressure plasma treatment technology. It is an innovative technology for surface cleaning, activation and coating.

- Power Supply : 220( -10% )~ 230( +10% ) Vac 50/60Hz,

- Fuse : 5A/250V

- Frequency : 25 KHz ~ 35 KHz

- Working Load : 2KV ~ 7KV

- Maximum Output : 400W / 500W

- Efficiency : >95% (Maximum Output)

- Working pressure : 0.1MPa~0.5MPa (1kg~5kg)

- Pneumatic Pressure:

–Input:0.30MPa~1.00Mpa

–For pressure above 1Mpa(10kg),additional valve required.

–Mounting:Φ8mm

–Normal air used. For specific requirement, other types such as hydrogen can be used

–Non grease and wet air supply. - Dimensions:

–Main Body : 165mm(W)X 365mm(H) X 460mm(L)

–Weight : 10Kg

–Blower Weight : 1kg - Cable length : ≥ 2300mm

XIOX-1000A

Air Jet Plasma Module

This equipment uses normal pressure plasma treatment technology. It is an innovative technology for surface cleaning, activation and coating.

Power Supply : 220( -10% )~ 230( +10% ) Vac 50/60Hz,

Fuse : 10A/250V

Frequency : 25 KHz ~ 35 KHz

Working Load : 2KV ~ 7KV

Maximum Output : 800W / 1000W

Efficiency : >95% (Maximum Output)

Working pressure : 0.1MPa~0.5MPa (1Kg~5Kg)

Pneumatic Pressure:

-Input:0.30MPa~1.00Mpa

–For pressure above 1Mpa(1kg),additional valve required.

-Mounting:Φ8mm

–Normal air used. For specific requirement, other types such as hydrogen can be used

-Non grease and wet air supply.Dimensions:

–Main Body : 400mm (W) X 150mm (H)X 470mm (L)

–Weight : 10Kg

–Blower Weight : 2kgCable length : ≥ 2300mm

Product Details

1.1.1

- Plasma State

1.1.2

- Matter receives energy and changes from solid to liquid, and then from liquid to gaseous. Strong energy is excited to gas molecules, ionized and transformed into another gas aggregation state, the plasma state. When high-energy plasma bombards the surface of other substances, chemical and physical reactions occur, resulting in some beneficial functional applications.

Plasma surface treatment of material, have the following major effects:

-Activation: Significantly improves the immersion performance of the surface, forming an active surface

-Cleaning: Remove dust and oil, finely clean and de static.

-Coating: A surface that provides functionality through surface coating treatment Improves surface adhesion and improves the reliability and durability of surface bonding. - After the use of normal pressure plasma technology treatment, whether it is all kinds of polymer plastics, ceramics, glass or metal and other materials can obtain surface energy improvement. Through this process, the improvement of surface tension characteristics of the material can be more suitable for industrial coating, bonding and other treatment requirements.

Such as electronic products, LCD screen coating treatment, chassis and buttons and other structural parts of the surface oil-spray screen, PCB surface decontamination cleaning, lens glue paste before processing, and so on - Pre-paste treatment of automotive industry lampshades, brake pads, door sealant strips, fine and harmless cleaning of metal parts in the mechanical industry, pre-coating treatment of lenses, pre-sealing treatment of various industrial materials… Wait a minute.

The processing of the adhesive on the edge position in the printing and packaging paste box machinery, etc.

1.2

- Quality and Innovation

Normal pressure plasma technology has a wide range of applications, which makes it a widely watched surface treatment process in industrial printing, coating and bonding processes. Through the use of this innovative surface treatment process, modern manufacturing processes can achieve the goal of high reliability, efficiency, low cost and environmental protection. - Plasma technology is used in industrial production, there will be no toxic substances and chemicals, will not constitute environmental pollution or harm to human health.

1.3

- Device Features

This equipment has the following technical characteristics:

Reliable system performance System equipment self-test and comprehensive process status and parameter monitoring, monitoring, and alarm protection.

Flexible control for host panel control, remote control, human control, or automated online control. Suitable for a variety of use occasions, a variety of jet gun nozzle selection, can be suitable for a variety of processing applications.

XIOX-500-05A

- Power Supply : 220( -10% )~ 230( +10% ) Vac 50/60Hz,

- Fuse : 5A/250V

- Frequency : 25 KHz ~ 35 KHz

- Working Load : 2KV ~ 7KV

- Maximum Output : 400W / 500W

- Efficiency : >95% (Maximum Output)

- Working pressure : 0.1MPa~0.5MPa (1kg~5kg)

- Pneumatic Pressure:

–Input:0.30MPa~1.00Mpa

–For pressure above 1Mpa(10kg),additional valve required.

–Mounting:Φ8mm

–Normal air used. For specific requirement, other types such as hydrogen can be used

–Non grease and wet air supply. - Dimensions:

–Main Body : 165mm(W)X 365mm(H) X 460mm(L)

–Weight : 10Kg

–Blower Weight : 1kg - Cable length : ≥ 2300mm

XIOX-1000A

Power Supply : 220( -10% )~ 230( +10% ) Vac 50/60Hz,

Fuse : 10A/250V

Frequency : 25 KHz ~ 35 KHz

Working Load : 2KV ~ 7KV

Maximum Output : 800W / 1000W

Efficiency : >95% (Maximum Output)

Working pressure : 0.1MPa~0.5MPa (1Kg~5Kg)

Pneumatic Pressure:

-Input:0.30MPa~1.00Mpa

–For pressure above 1Mpa(1kg),additional valve required.

-Mounting:Φ8mm

–Normal air used. For specific requirement, other types such as hydrogen can be used

-Non grease and wet air supply.Dimensions:

–Main Body : 400mm (W) X 150mm (H)X 470mm (L)

–Weight : 10Kg

–Blower Weight : 2kgCable length : ≥ 2300mm

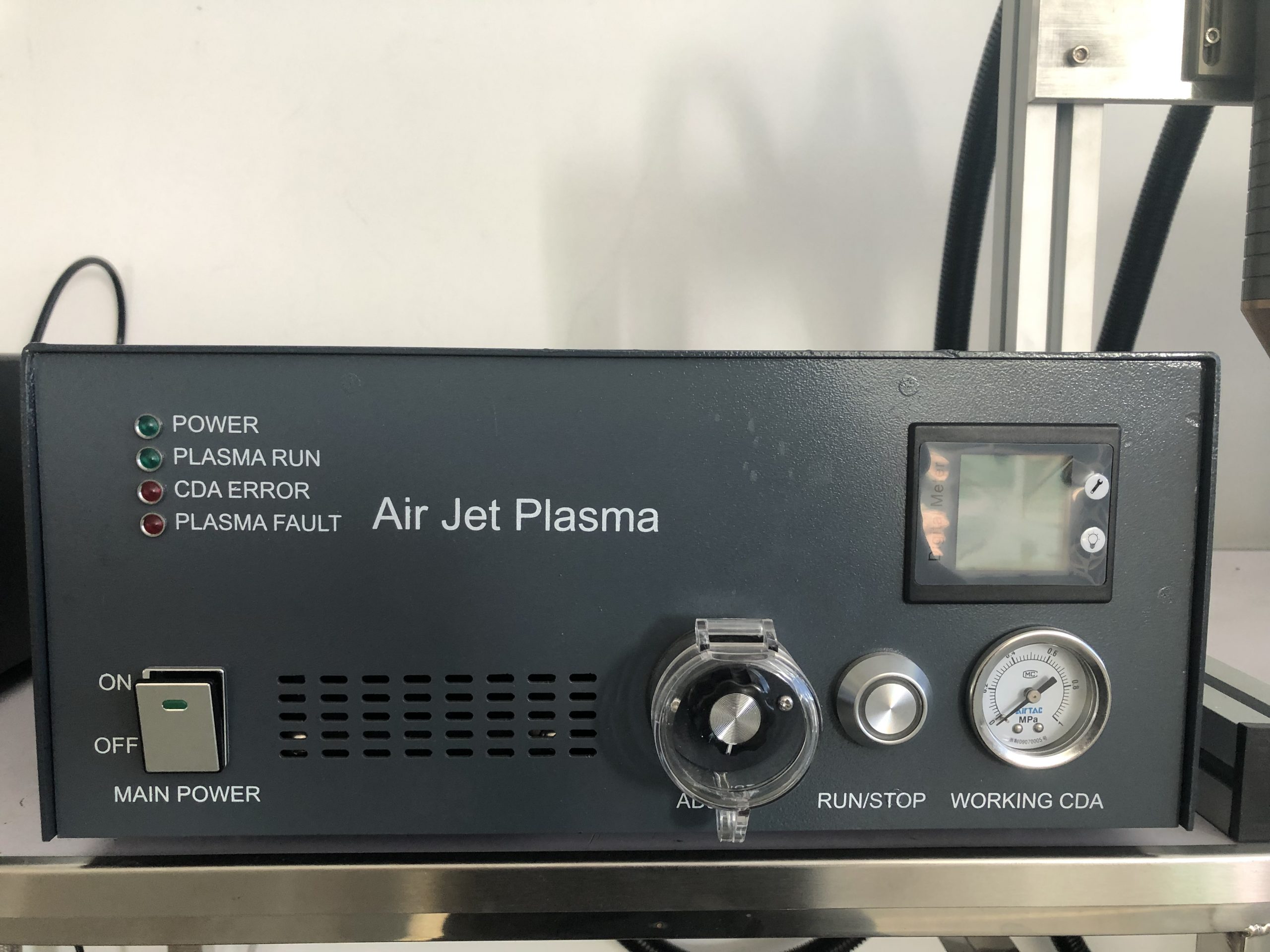

3.2

- Pressure Indicator

Displays the current operating air pressure value. The user can obtain the appropriate operating air pressure through the air pressure regulation valve at the rear of the machine. - The size of the air pressure has some effect on the processing effect of plasma and the operating temperature of plasma. The higher the air pressure, the lower the plasma concentration and the corresponding temperature. The actual working air pressure should be adjusted according to the needs of plasma treatment material type, process requirements, processing speed and the corresponding output power settings and many other factors.

- Excessive or low operating air pressure can cause unstable plasma output jets. The operating air pressure range sets the minimum and maximum values, and the host automatically shuts down and alarms when the air pressure is below 0.07MPa or when no compressed air source is available.The operating air pressure value should generally not exceed the range of 0.05MPa (0.5 kg) to 0.5MPa (5 kg).

- Recommended working pressure:

| Output power range | Pressure |

| 400-600W | 0.15-0.2Mpa |

| 600-800W | 0.2-0.3Mpa |

| 800-1000W | 0.3-0.4Mpa |

*Note: For reference only. Use according to requirement.

3.3

- Air pressure regulation valve

Used to adjust to the appropriate working air pressure. Gently pull out the knob to unlock, rotate clockwise to increase air pressure, and turn counterclockwise to reduce air pressure. Press down on the inlet knob to lock the air pressure control valve.

3.4

- Power switch

When this switch is off, turn off all power supply in the machine. - When the switch is switched on, the compressed air supply valve is activated and when the switch is closed, compressed air in the machine is switched off Supply valve.

3.5

- Remote (external) start-stop control signal input

This device provides an external (or remote) switch mode to control start and stop, making it easy for users to use the device to achieve automatic control when online with other devices. - When SW1 is disconnected from SW2, it means that the foreign control executes the Off command

- When SW1 is connected to SW2, it means that the foreign control executes the “on” command

3.6

- Compressed air input

Mounting: 8mm

Gas pressure requirement range: 0.30Mpa-1.00Mpa (3Kg-10Kg) - If the air source pressure exceeds 1Mpa (10Kg), an external pressure limit valve is required.

- The gas source can use normal air. Nitrogen or other specific gases can be used when required by special processes.

- If no compressed gas is available, or if the air pressure is below 0.03Mpa (0.3Kg), the opportunity is immediately shut down and the alarm is raised.

- Warning: The requirement must be oil-free and water-free.

3.7

- Single-phase 220/230V power input socket

- Warning: The supporting power supply must be single-phase three-wire, i.e. a reliable connection with ground wire must be guaranteed.

3.8

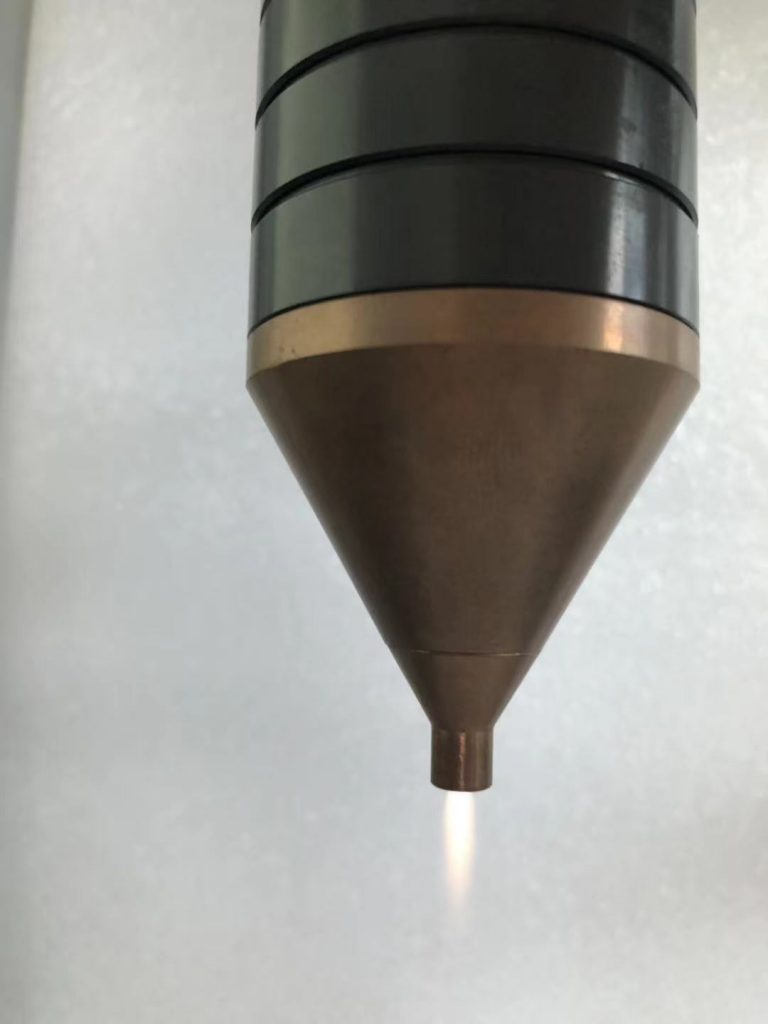

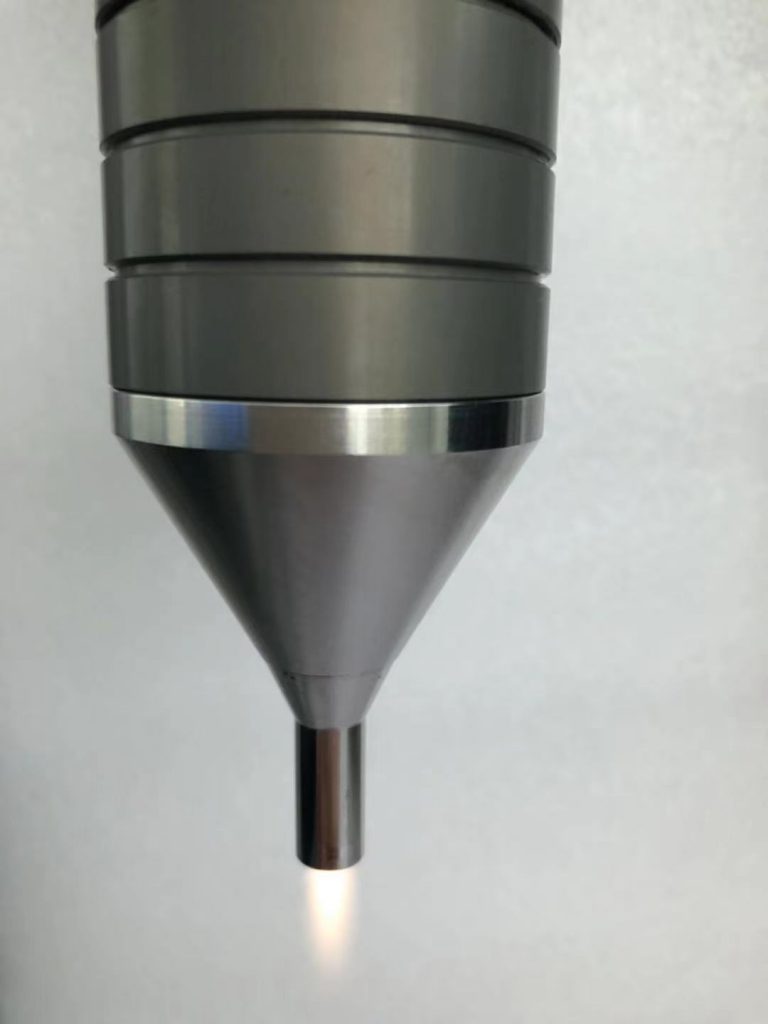

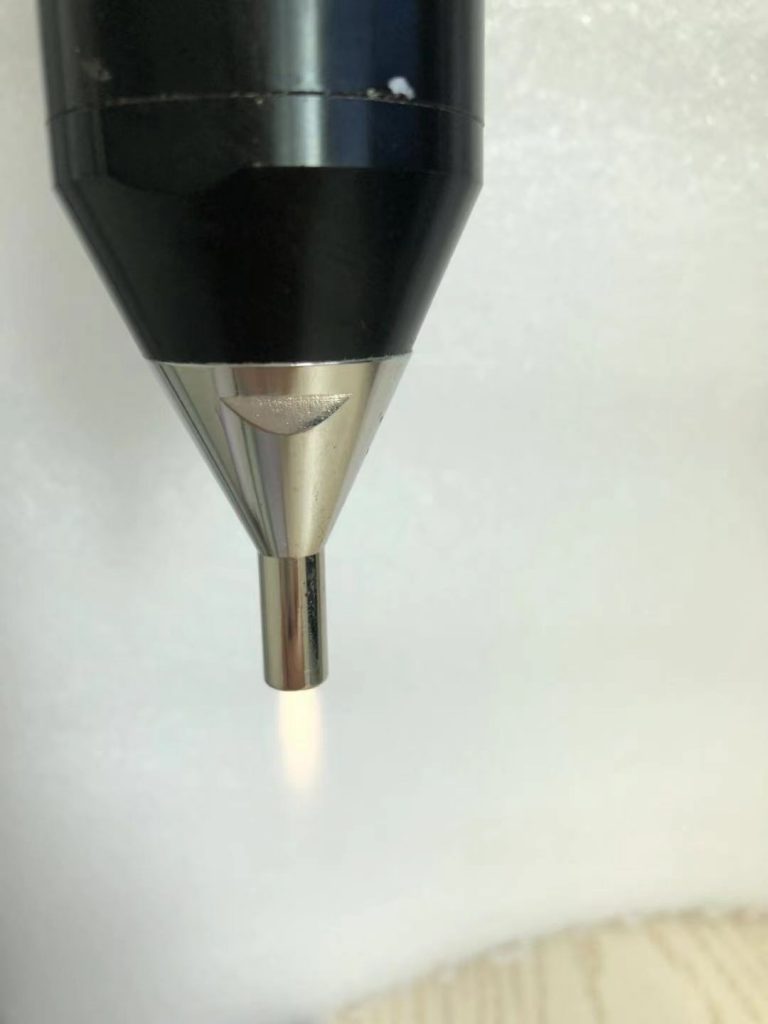

- Plasma spray gun and high-voltage cable interface

Plasma spray gun is an important component of plasma jet module. - The surface of the treated material is generally in the plasma jet area at a distance of 10-20mm.

- The plasma gun produces a certain high temperature when operating and is as integrated as possible with the metal bracket during installation to facilitate heat dissipation. The treated material is generally moved through the plasma gun port.

- Warning: When working, the treated material must not stay in the plasma jet zone for long periods of time to avoid damage to high temperatures or risk of combustion! Prevents burns to the hands during operation!

- Warning: High voltages in plasma guns and high-voltage cables are available to prevent accidental damage and risk of electric shock.

- After long-term use, the plasma spray gun will produce a certain amount of pollution, need regular maintenance and cleaning.

3.9

- Control panel

3.9.1 Normal operating status light

-When the power is powered on, the green light lights up in standby

-After normal discharge, the red light comes on - 3.9.2 Working fault status, alarm indicator

-When the air pressure is under pressure, overpressure, the alarm light is on, the shield shows: gas under voltage or gas overpressure

-Input voltage is too high alarm, shield display: input voltage is too high

-Input voltage is too low alarm, shield display: input voltage is too low

-Output open alarm, shield display: Power output is off

-Output short-circuit alarm, shield display: power output short-circuit

-Temperature too high alarm, shield display: power over heated. - 3.9.3 Run/Stop button

-When the device is down, press this button to start the device.

-When the device is running, press this button to pause the device. - 3.9.4 Parameter setting, power regulation twist

-Increase power at the up button when the device is down and running.

-When the equipment is down and running, reduce the power by the down button. 3.9.5 Display Panel

-Refer to 3.9.2 to describe the device alarm state, the alarm content will be displayed on the screen

-By another 3.9.4 method, the power output power is displayed on the screen while the device is running.

4.1

- Preparation

-The customer refers to the previous section and actually does the necessary connection.

Note: Before powering on, make sure that the power switch is switched off and point the plasma gun at a safe position, as the plasma airflow is high-energy when the plasma gun is operating, causing a high temperature rise on the surface of the object under continuous pressure, causing scorching damage and burning combustible material.

4.2

- Start/stop control

-When the power is on, press the power switch, the system self-test into the operating state, POWER light on.

-The front panel of the host presses the start button, the device works to start, the running light is on, and the plasma spray gun spits fire.

-The front panel of the host presses the stop button and the device stops working and goes into standby.

-This device has external control (remote control) function. Through the “external control (remote control) start-stop control signal input” can be remote control or external automation production line connection, to achieve automatic control.

-When the “external control (remote control) start-stop control signal input” plug configured by this machine is inserted into the corresponding socket, the external control function starts. When external control is enabled, the front panel proximity fails. This function is automatically cancel when the plug is not inserted.

4.3

- Output power adjustment and display

-Depending on the actual use, the user can adjust the output power size at will within the rated maximum output power range.

-When the device is operating, the power display shows voltage, current, and output power.

-Increase power: When the device is down and running, press the up button in the set area to increase power.

-Reduce power: When the device is down and running, set the area to press the down button to reduce power.

–Tip: When the user adjusts the output power, attention needs to be paid to the working air pressure adjustment fit.

4.4

- Alarm

-In order to facilitate the user to operate and maintain the equipment, the native equipment has a variety of necessary equipment protection and fault alarm signal. Such as: the user’s field use of power voltage defects, the lack of gas supply, installation of connected equipment at the time of the device can give alarm protection in more aspects and so on.

-In the event of a failure, the equipment is automatically shut down immediately for protection. The host will have a red alarm light display and a buzzer alarm, and the alarm content will be displayed on the screen.

-After the user troubleshoots, the alarm light goes out automatically and the buzzer stops sounding. It is recommended that the user turn off the host power check when troubleshooting to ensure safety!

–The following describes the failure alarm functions and basic solutions of this machine:4.4.1 The input voltage is too high for an alarm

The supply voltage that supplies this equipment exceeds the maximum allowable voltage and the device alarm is protected. In the event of this alarm, the user should switch off the main switch as soon as possible to prevent deeper damage to the device due to excessive voltage. The user needs to ensure that the device is operating within the rated voltage range.

4.4.2 The input voltage is too low for an alarm

The power supply voltage to this equipment exceeds the minimum allowable voltage and the device alarm is protected. The user needs to ensure that the device is operating within the rated voltage range.

4.4.3 Output alarm

Equipment core components failure, the user needs to check two aspects in turn: 1) plasma is normal fire or intermittent fire, check whether the air pressure is normal at work, such as the air pressure number display parameters normal also need to check whether the jet gun trachea is smooth;

4.4.4 Output short-circuit alarm

The main electrical core part of the equipment is OK, the user first check whether the plasma gun is properly grounded. If the ground is normal, the power control or output part fails and requires professional service.

4.4.5 The temperature is too high to alarm

The temperature of the core device is outside the normal range and requires shutdown protection. Users need to check the following in turn: 1) whether the operating environment temperature exceeds (greater than 40 degrees C), 2) whether the main box is placed in a closed cavity, can not dissipate heat, 3) the main box cooling fan is working properly, 4) equipment internal failure, need professional maintenance;

4.4. 6 Pneumatic under/over pressure alarm

This alarm occurs if the intake pipe is not connected or the intake pressure is insufficient. It is necessary to check that the intake pipe is properly connected and adjust the regulator valve to achieve the appropriate working air pressure.